Heat & Oil Resistant Conveyor Belts

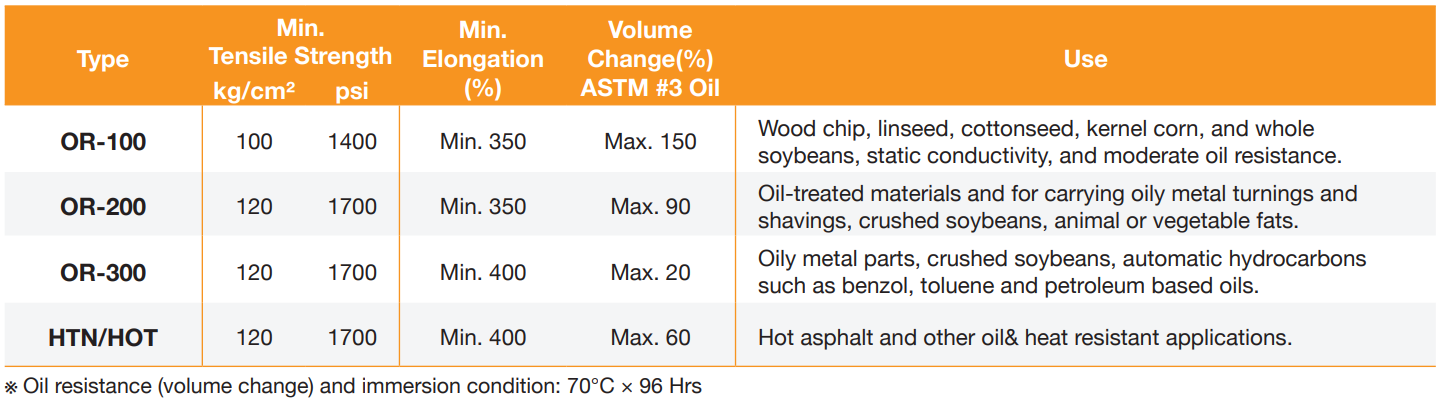

The cover rubber is especially compounded for the applications requiring resistance to oils. It has outstanding abrasion, ozone and weather resistance. This Lorbrand conveyor belt is recommended for the conveyor lines causing swelling and sponginess by oils.

Grease, mineral oil and solvents may cause damages to normal textile conveyor belts. Even a short exposure to these substances may effect a swelling of the cover rubber. MonsterBelt® product portfolio comprises the qualities MOR (medium oil resistant) and OR (oil resistant). The product specifications are also available in cross rigid XE-fabric.

Application areas

• Chemical industry

• Fertilizer industry

• Iron and steel industry

• Feed industry

• Grain silo

• Glass industry

• Wood industry

• Metal processing industry

• Recycling industry