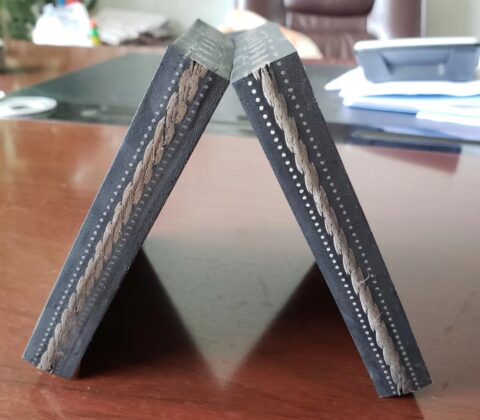

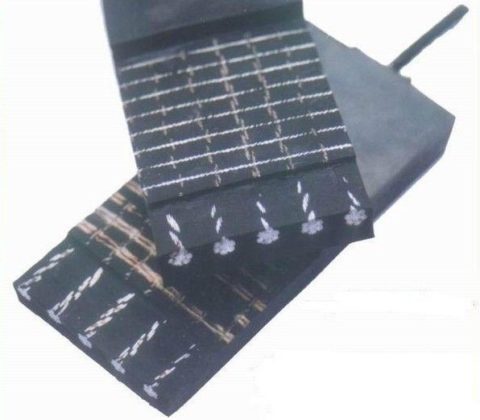

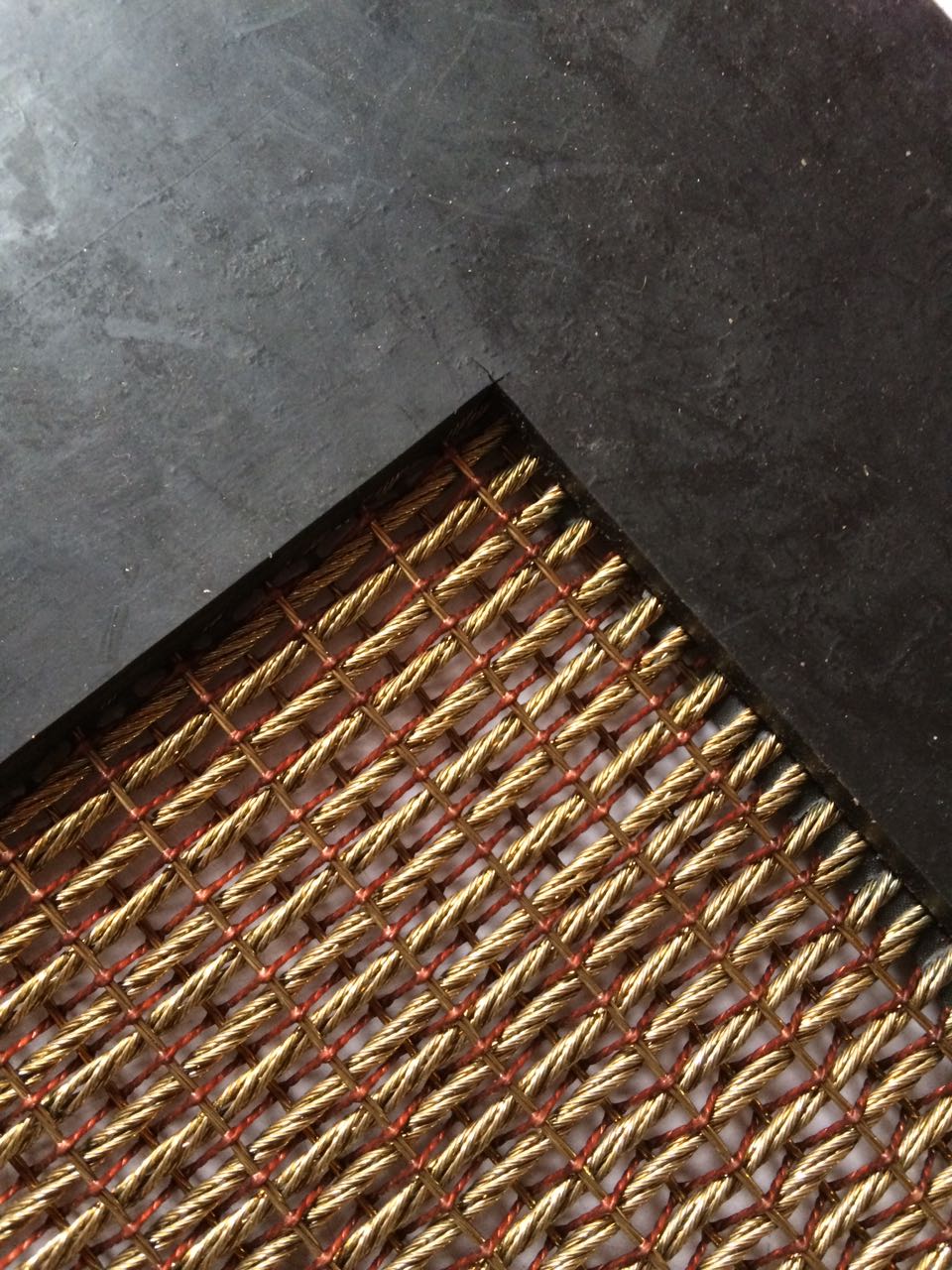

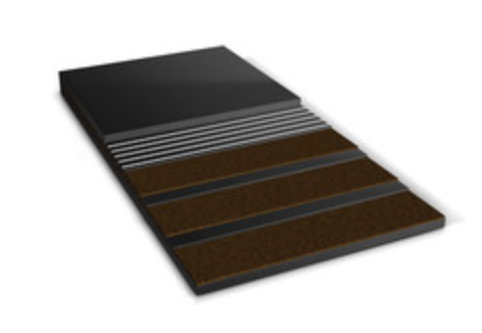

Transverse reinforcing cord belt ( Cross Stabilized Rubber Conveyor Belts ) is a belt with high transverse rigidity specifically designed for flat use. Its main purpose is to be the base for belts with corrugated sidewalls and cleats.

Reinforced Conveyor Belts is also widely used as a cover belt for the safe protection of channels and gutters. It is available with either a textile or steel carcass construction.