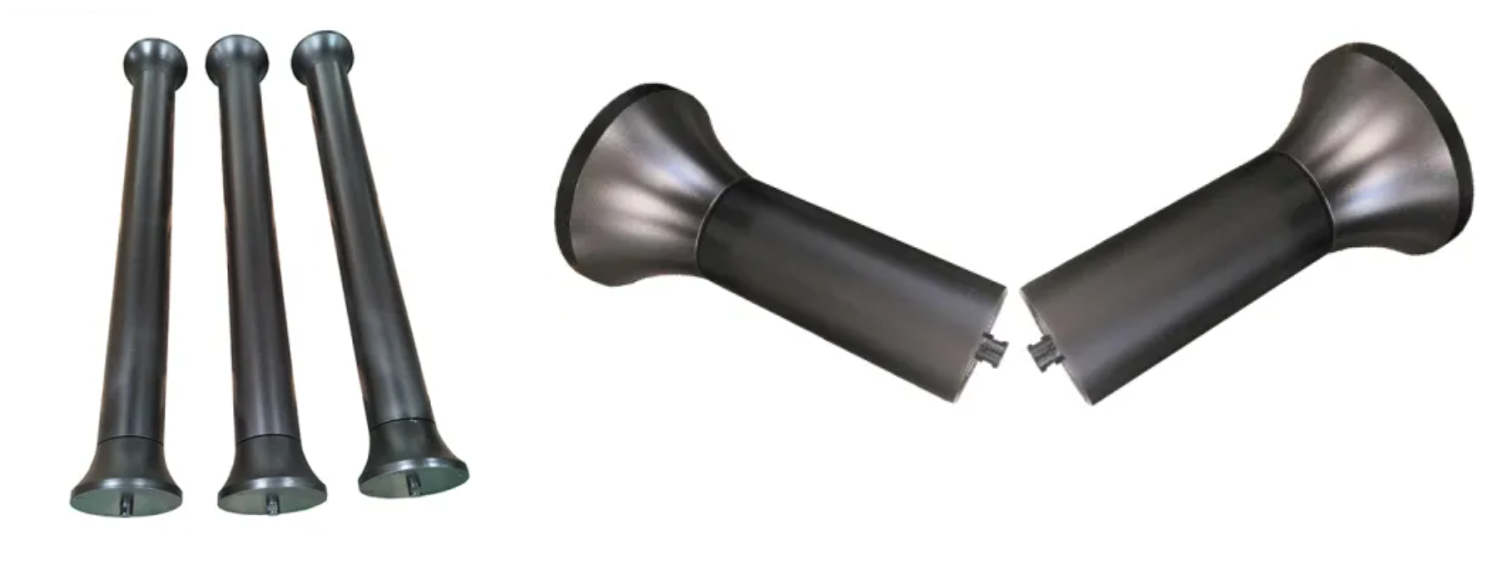

Friction roller, underground coal mining self align conveyor roller

Friction roller with strong ability to prevent the conveyor belt injury and running deviation, using the friction resistance and friction wheel radian mechanism of wandering To prevent and correct conveyor belt running deviation, achieve the heart function.

Friction Roller Conveyors is to support the conveyor belt and the weight of the material. Roller must be flexible and reliable operation. Reduce the friction with roller conveyor belt, to take up of the total cost of more than 25% of the conveyor belt conveyor life plays a key role. Although the roller in the belt conveyor is a smaller part, structure is not complicated, but to create high quality roller is not easy. If the conveyor belt running deviation, relative to the center of gravity to which side which partial friction will increase, in under the action of friction, high friction will be at the end of the conveyor belt running direction generate oscillation, the function transfer belt of the automatic swing back to the operation of the middle route. Friction roller is widely used in mining, power, metallurgical, chemical, food, construction, ports, docks and other form a complete set of belt conveyor.